Returnable Transport Packaging Market to Reach USD 50.17 Billion by 2035, Driven by Sustainability and Supply Chain Efficiency | Future Market Insights, Inc.

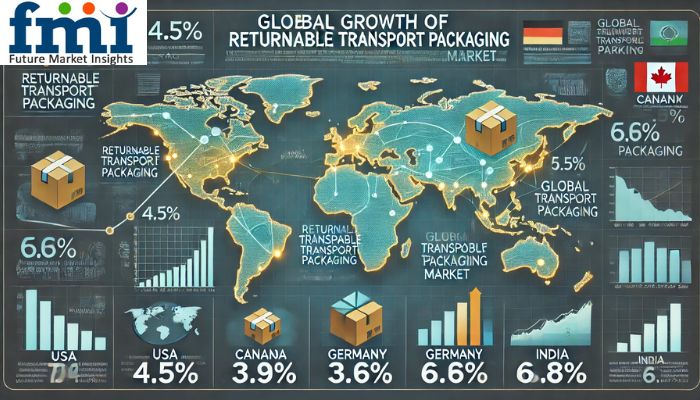

Germany's returnable transport packaging market is driven by the auto industry's shift to standardized reusable packaging for efficiency and sustainability. Leading carmakers like Volkswagen, BMW, and Mercedes-Benz rely on returnable plastic crates, bespoke dunnage, and foldable pallet boxes for shipping precision parts, batteries, and electronics.

/EIN News/ -- NEWARK, Del, Feb. 27, 2025 (GLOBE NEWSWIRE) -- The global returnable transport packaging (RTP) market is poised for remarkable growth, with sales projected to surge from USD 31.09 billion in 2025 to USD 50.17 billion by 2035. This expansion reflects a CAGR of 4.9%, driven by the increasing demand for cost-efficient, sustainable, and reusable logistics solutions.

Returnable transport packaging encompasses a broad range of reusable materials, including pallets, crates, totes, and intermediate bulk containers (IBCs), designed to streamline supply chain operations. These solutions reduce packaging waste, lower carbon footprints, and enhance cost efficiency, making them an integral part of modern logistics systems.

With businesses striving for sustainable supply chain practices, leading industries such as food & beverages, pharmaceuticals, automotive, and retail are embracing RTP solutions to minimize environmental impact and operational expenses.

Reusable transport packaging helps in providing safety and security to the product along with reducing the cost which benefits the manufacturers as well as the vendor/customer. Higher demand for lightweight packaging for cost-benefit often associated with it bolsters the sales of returnable transport packaging.

Request Your Sample Now and Explore Market Opportunities: https://www.futuremarketinsights.com/report-sample#5245502d47422d34373935

The Rising Demand for Durable and Eco-Friendly Pallets in Modern Supply Chains

Pallets form the foundation of returnable transport packaging (RTP), offering a long-lasting, cost-effective, and environmentally responsible option for handling and shipping goods across sectors. Pallets, particularly those constructed of plastic, metal, and composite materials, are increasing popularity because of their reusability, durability, and ability to reduce waste. Unlike single-use packaging, returnable pallets provide a closed-loop supply chain, reducing material consumption and overall transportation costs.

How Will the Demand for In-Transit Damage Protection Solution Impact Reusable Transport Packaging Market?

Local consumers are more inclined towards ‘value for money, which has compelled logistics service providers in the region to opt for reusable transport packaging solutions such as dunnage airbags, crates, and others. Growing urbanization in the emerging economies has created more demand for in-transit damage protection solutions such as dunnage airbags.

Dunnage airbags have therefore witnessed maximum usage by packers and movers. FMI predicts sales in Asia Pacific to continue growing in tandem with the expansion of manufacturing and packaging industries.

This trend will continue well over the future as APAC emerges as a hotspot for sales of cost-effective packaging solutions. Dunnage airbags are usually made of paper which is environmentally friendly and therefore are expected to be used increasingly by by medium- to small-sized packers & movers.

How is the Expansion of Chemical Industry Aiding Returnable Transport Packaging Market Growth?

The use of the container is growing at a fast pace for the transportation of chemicals such as paints, coatings, and dyes. IBCs are one of the most suitable returnable transport packaging solutions for the shipping of harmful and corrosive fluids. They also play a dual role as an effective warehouse storage option.

Paints, coatings, and dyes is a demanding industry that requires storage and transport containers that can stay inert to various chemicals reactions and successfully deliver the product without affecting its quality.

A significantly large number of paint and coatings products meet the criteria for hazardous materials that require a safe container or packaging solution. Improper packaging solutions can harm the property of chemicals as well as harm the surrounding.

The need for safe, cost-effective, and secure packaging solutions is propelling the demand for returnable transport packaging. The need for secure transportation of hazardous products in the paints, coatings, and dyes industry is attributed for boosting the demand for shipping containers.

"The Returnable Transport Packaging (RTP) market is gaining traction as businesses prioritize sustainability and cost-efficiency. With rising demand for eco-friendly logistics, RTP solutions like pallets, crates, and containers are reshaping supply chains." Says a Lead Consultant Ismail Sutaria in Packaging at Future Market Insights (FMI).

Key Takeaways From the Returnable Transport Packaging Market

- The global returnable transport packaging industry recorded a CAGR of 2.3% between 2020 and 2024.

- Market growth remained positive, reaching USD 30,396.7 million in 2024.

- The USA is expected to lead in North America with a projected CAGR of 4.5% through 2035.

- India is anticipated to witness significant growth in South Asia & Pacific, with a CAGR of 6.8% by 2035.

- Intermediate Bulk Containers (IBC) are projected to grow at a CAGR of 5.6% from 2025 to 2035.

- The food and beverage sector is expected to expand at a CAGR of 4.7%.

Plastic’s Ongoing Expansion in the Returnable Transport Packaging (RTP) Industry

Plastic continues to dominate as the fastest-growing material in the Returnable Transport Packaging (RTP) industry, driven by its durability, lightweight nature, and reusability. One of the key innovations in this sector is plastic-corrugated packaging, which utilizes extruded twin-wall plastic sheets made from high-impact polypropylene, polyethylene, and other plastic resins.

This advanced material mirrors the structure of corrugated fiberboard, featuring fluted ribs that reinforce the upper and lower surfaces for added strength and flexibility. The versatile design of plastic-based RTP solutions allows for the production of handheld boxes, bulk bins, and other reusable transport containers, offering enhanced protection, longevity, and cost-effectiveness compared to traditional materials.

High Initial Investment Costs: A Challenge for the Returnable Transport Packaging Industry

The returnable transport packaging (RTP) business faces a substantial challenge due to high initial investment costs. Unlike single-use or throwaway packaging, returnable options like pallets, crates, and containers need a significant upfront capital investment. Businesses must spend money not just for procuring long-lasting packaging materials, but also for building effective reverse logistics systems to ensure their continual reuse.

What are the Key Trends Shaping Returnable Transport Packaging Market?

Innovations by key players operating in the returnable container market offers smart packaging solutions which include pallets or IBCs or crates comprised of Radio Frequency Identification (RFID) microchips to help collecting information, tracing, tracking, and recording.

These innovations also are intended to optimize inventory management. The increasing demand for smart packaging is anticipated to boost the demand for returnable containers integrated with advanced technologies for offering advanced solutions. It also helps in making the supply chain more automated and saves time.

Stay Ahead of the Curve—Gain exclusive insights and uncover new opportunities with our Packaging Formats Industry Analysis Reports.

Understanding the Key Catalysts Behind the Returnable Transport Packaging Market

- Cost Efficiency and Sustainability: RTP helps reduce packaging waste and costs in the long term by enabling the reuse of packaging materials. Companies are increasingly focused on sustainability, and returnable packaging offers a more eco-friendly alternative to single-use packaging.

- Environmental Regulations and Corporate Responsibility: Increasing environmental concerns and stricter regulations around waste management are pushing companies to adopt sustainable packaging solutions. RTP aligns with these regulations by reducing the environmental impact of packaging waste.

- Supply Chain Optimization: RTP streamlines the logistics process by reducing packaging material costs and simplifying inventory management. The use of durable, reusable packaging leads to more efficient storage, handling, and transportation in supply chains.

- Improved Product Protection and Durability: Returnable packaging is designed to be robust and durable, offering better protection for products during transportation. This reduces product damage and waste, making it a more reliable solution compared to disposable packaging.

-

Rising Demand for Automation in Packaging Systems: As industries increasingly integrate automation into their operations, RTP offers compatibility with automated packaging and material handling systems. This improves efficiency, reduces manual labor, and enhances the overall speed of the supply chain.

Competitive Landscape

Key companies in the returnable transport packaging industry are investing in the development of innovative sustainable solutions, as well as forming collaborations. Key returnable transport packaging providers have also been acquiring smaller players to expand their footprint and penetrate the returnable transport packaging industry in numerous locations.

Recent Industry Developments in the Returnable Transport Packaging Market

- Veritiv completed the acquisition of Orora Packaging Solutions in September of 2024. This purchase aims to improve Veritiv's specialty packaging distribution capabilities, while Orora focuses on its beverage packaging business.

- The shareholders of International Paper and DS Smith authorized a merger in October 2024, with pro forma sales expected to exceed USD 28 billion. This merger is likely to boost their position in the RTP industry.

- Logson Group purchased Challenge Packaging in February 2024 to broaden its products in England's southeast region and boost its position in the RTP market.

Key Players of the Returnable Transport Packaging Industry

- Grief, Inc.

- Brambles Limited

- Mauser Packaging Solutions

- Schoeller Allibert Services B.V.

- DS Smith Plc

- Time Technoplast Ltd.

- Berry Global, Inc.

- Cordstrap B.V.

- Schuetz GmbH & Co. KGaA.

- Supreme Industries Limited

- PalletOne, Inc

- Balmer Lawrie & Co. Ltd.

- Craemer Holding GmbH

- Cabka Group GmbH

Get the Complete Story—Read More About Our Latest Report!

https://www.futuremarketinsights.com/reports/returnable-transport-packaging-market

Key Segments of the Returnable Transport Packaging Industry

By Material:

In terms of material, the industry is divided into metal, plastic, paper, wood.

By Product Type:

In terms of product type, the industry is segregated into IBC, pallets, plastic crates, layer pads, drums, dunnage bags.

By End Use:

The market is classified by end use such as building & construction, food & beverages, chemical, retail, industrial, logistics.

By Region:

Key countries of North America, Latin America, East Asia, South Asia & Pacific, Western Europe, Eastern Europe, and the Middle East & Africa have been covered in the report.

Have a Look at Related Research Reports on the Packaging Domain:

Sales of returnable transport packaging in North America are expected to be valued at USD 28.53 billion in 2023 and USD 42.11 billion by 2033.

The transport packaging market size is estimated to be worth USD 29.2 billion in 2025 and is anticipated to reach a value of USD 42.0 billion by 2035.

Consumer electronics packaging refers to the materials and methods used to protect, display, and transport consumer electronics products, such as smartphones, laptops, cameras, and other gadgets, from the manufacturer to the end consumer.

The market for medical device packaging is estimated to generate a market size of USD 43.2 billion in 2025 and would increase to 67.7 billion by 2035.

Blister packaging is a type of packaging commonly used for small consumer goods, pharmaceuticals, and medical devices. It consists of a pre-formed plastic cavity or pocket, usually made from materials like PVC, PET or aluminum, which holds the product.

The global sanitary food & beverage packaging market is likely to reach USD 40.72 billion in 2023. The market is expected to surpass USD 52.55 billion by 2033, exhibiting a CAGR of 2.6% between 2023 and 2033.

The rise in demand for authentic beauty products is driving significant growth in anti-counterfeit cosmetic packaging, ensuring product integrity and consumer trust in an increasingly competitive market.

The global lubricant packaging market is estimated to top USD 12.06 billion in 2023 and is projected to reach USD 20.4 billion by 2033, moving forward at a CAGR of 5.4%.

The eye cosmetic packaging sector is experiencing rapid growth, driven by innovative designs and increasing consumer demand for premium, eco-friendly packaging solutions that enhance product appeal and functionality.

The demand for single-portion cosmetic packaging is surging, driven by consumer preferences for convenience, hygiene, and precise application, alongside brands’ desire to enhance product presentation and reduce waste.

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer, Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Distribution channels: Book Publishing Industry ...

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release